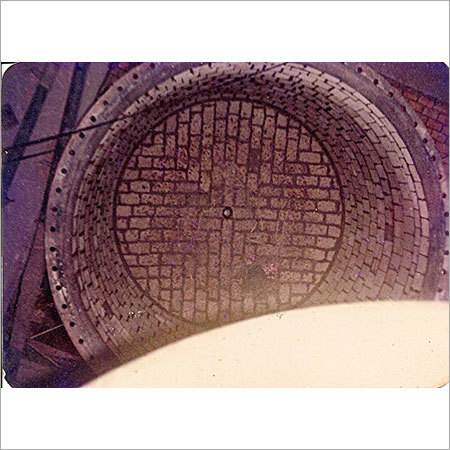

Chemical Resistant Tile Lining Of Reaction Vessel

2500 INR/Square Meter

Product Details:

- Usage Chemical processing, acid storage, pharmaceutical manufacturing

- Purity High purity alumina (>90%)

- Thickness 10 mm to 25 mm (customizable)

- Installation Type In-situ cementation / epoxy bonded lining

- Material Grade Class I, IS 4457 / ASTM C279

- Form Solid tile blocks

- Diameter Custom fit to vessel dimensions, typically 1 m to 6 m

- Click to View more

X

Chemical Resistant Tile Lining Of Reaction Vessel Price And Quantity

- 2500 INR/Square Meter

- 150 Square Meter

Chemical Resistant Tile Lining Of Reaction Vessel Product Specifications

- Rectangular, Square, Custom shapes

- Off White, Cream, Black, Grey

- Excellent mechanical and chemical durability

- Tile lining for reaction vessel in chemical/pharmaceutical industries

- High chemical resistance, abrasion proof, leak proof

- Chemical Resistant Tile Lining

- Reaction Vessel / Reactor

- Can withstand heavy chemical loading

- Custom fit to vessel dimensions, typically 1 m to 6 m

- Solid tile blocks

- Dependent on tile size and vessel dimensions

- Class I, IS 4457 / ASTM C279

- In-situ cementation / epoxy bonded lining

- 10 mm to 25 mm (customizable)

- High purity alumina (>90%)

- Anti-corrosive, Glazed/Matte Finish

- High Alumina Ceramic / Acid Resistant Tiles

- Chemical processing, acid storage, pharmaceutical manufacturing

- Customized sizes available (Common: 230 x 115 mm, 150 x 150 mm)

Chemical Resistant Tile Lining Of Reaction Vessel Trade Information

- 5000 Square Meter Per Week

- 2-7 Days

Product Description

Take advantage of the new generation of Chemical Resistant Tile Lining for reaction vessels, utilizing eminent high alumina ceramic or acid-resistant tiles. Designed to offer radiant protection, this tile lining system employs phenolic or epoxy-based mortar, delivering commanding bond strength to steel, FRP, or concrete substrates. Enjoy reduced maintenance and minimal water absorption while ensuring excellent abrasion and chemical resistance in harsh environments. The robust, expertly installed lining withstands thermal shock and heavy chemical loads, guaranteeing a leak-proof, long service life and compliance with global standards like ASTM C-279 and IS 4457.

Site Application, Surface Advantage, and Applicability

Chemical Resistant Tile Lining is eminently suited for chemical processing, acid storage, and pharmaceutical manufacturing sectors. It is applied inside reaction vesselsbe they MS, SS, FRP, or RCCwhere robust command over corrosion, leaks, and chemical damage is crucial. Take advantage of its anti-corrosive glazed or matte finish, offering easy-to-clean and radiant surfaces even in the most demanding industrial conditions, on tough substrate surfaces like vessel steel or fiber-reinforced polymer.

Export Markets, Packaging, and Sample Policy

Our tile linings are extensively exported worldwide, with prominent markets across Asia, Europe, Africa, and the Middle East. Packaging details ensure safe drop-off and minimize transit damage; tiles are handed over in sturdy, export-grade crates. On-site delivery is timely and customizable per customer requirements. Sample policies are flexiblesamples can be provided for quality assurance, ensuring confidence in product selection and application prior to order finalization.

Site Application, Surface Advantage, and Applicability

Chemical Resistant Tile Lining is eminently suited for chemical processing, acid storage, and pharmaceutical manufacturing sectors. It is applied inside reaction vesselsbe they MS, SS, FRP, or RCCwhere robust command over corrosion, leaks, and chemical damage is crucial. Take advantage of its anti-corrosive glazed or matte finish, offering easy-to-clean and radiant surfaces even in the most demanding industrial conditions, on tough substrate surfaces like vessel steel or fiber-reinforced polymer.

Export Markets, Packaging, and Sample Policy

Our tile linings are extensively exported worldwide, with prominent markets across Asia, Europe, Africa, and the Middle East. Packaging details ensure safe drop-off and minimize transit damage; tiles are handed over in sturdy, export-grade crates. On-site delivery is timely and customizable per customer requirements. Sample policies are flexiblesamples can be provided for quality assurance, ensuring confidence in product selection and application prior to order finalization.

FAQs of Chemical Resistant Tile Lining Of Reaction Vessel:

Q: How is the chemical-resistant tile lining installed in reaction vessels?

A: The tile lining is usually installed using a chemical-resistant mortar, such as phenolic or epoxy-based compounds, directly onto the prepared vessel surface. Tiles are fixed butt-jointed or with chemical-resistant grout, achieving high bond strength and exceptional durability.Q: What surfaces and vessel materials are compatible with this tile lining?

A: Our tile lining is compatible with MS (mild steel), SS (stainless steel), FRP (fiber-reinforced polymer), and RCC (reinforced concrete cement) vessels, making it versatile for various chemical and pharmaceutical applications.Q: Where can Chemical Resistant Tile Lining offer the most benefit?

A: This lining provides commanding protection and longevity when used in environments exposed to corrosive chemicals, such as chemical processing plants, acid storage facilities, and pharmaceutical manufacturing units.Q: What advantages does this tile lining offer in industrial environments?

A: The system delivers excellent abrasion, acid, and alkali resistance, features a leak-proof and radiant surface, and demands minimal, reduced maintenance, resulting in a long service life of up to 10+ years depending on operating conditions.Q: How does the delivery process work for export orders?

A: Export orders are securely packaged in sturdy crates to ensure safe transit. Tiles are handed over by our logistics partners directly to the customers specified location, ensuring timely and efficient delivery worldwide.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Acid Alkali Resistant Tile Brick Lining' category

|

GOOD EARTH MINERALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |