Epoxy Painting Works

450 INR/Square Meter

Product Details:

X

Epoxy Painting Works Price And Quantity

- 450 INR/Square Meter

- 150 Square Meter

Epoxy Painting Works Trade Information

- 5000 Square Meter Per Week

- 2-7 Days

Product Description

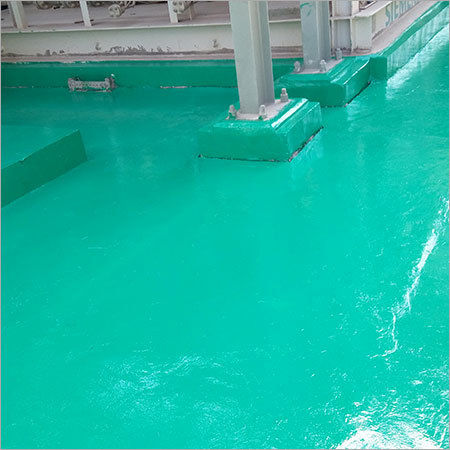

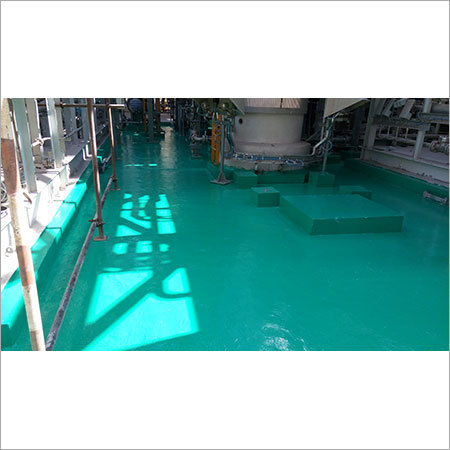

We provide Epoxy Painting Works and services to increase the strength and durability of the concrete floors in your factories, industries and various other commercial places such as libraries, railway stations, airports, metro stations, retail stores and many other places. It is manufactured by using top grade raw materials and high chemical additives in a proportionate manner to produce a fine viscos solvent. Our team of highly skilled professionals gives Epoxy Painting Works by using top grade materials by using advanced techniques and tools to make a smooth and excellent layer with high uniformity over the floors.Exceptional Performance for Demanding Environments

Designed for heavy traffic areas, our epoxy paint withstands impacts, abrasion, and up to 120C dry heat. Its robust formulation ensures lasting protection on concrete and metal surfaces while maintaining a glossy, attractive appearance. This makes it ideal for applications in factories, parking zones, hospitals, warehouses, and garages.

Simple and Versatile Application Process

This epoxy system offers user-friendly application, adaptable to brush, roller, or spray methods. Surface preparation is keyensure substrates are clean, dry, and free from grease or dust. With a manageable pot life of 4560 minutes and easy-to-follow 4:1 mixing ratio, professionals can achieve optimal results with minimal effort.

Long-Term Value and Safety

Low VOC emissions, excellent chemical and water resistance, and non-toxic properties after full cure make this paint a smart, safe choice. It meets international standards, offers custom color options, and provides anti-skid systems upon request, ensuring both safety and style for your industrial or commercial space.

FAQs of Epoxy Painting Works:

Q: How should the surface be prepared before applying epoxy paint?

A: For optimal adhesion, ensure the application surface is thoroughly cleaned, dry, and free from oil, grease, and dust. Proper surface preparation is crucial for maximizing the performance and longevity of the epoxy coating.Q: What is the recommended process for applying this epoxy painting system?

A: Start by applying an epoxy-based primer to the prepared surface. Mix the base and hardener at a 4:1 ratio, then apply the paint evenly by brush, roller, or spray. Allow at least 16 hours between coats, and ensure full cure over 7 days for best results.Q: When can the newly applied epoxy coating be recoated or exposed to traffic?

A: A minimum recoat interval of 16 hours is recommended between coats. The surface achieves dry-to-touch status in 68 hours and is hard dry in 24 hours. Light foot traffic is acceptable after 24 hours, while full chemical and mechanical resistance develops after 7 days.Q: Where can this epoxy paint be used effectively?

A: This epoxy coating is suited for use on industrial and commercial floors, warehouses, factories, parking areas, hospitals, and garages. Its impact resistance and chemical durability make it ideal for high-traffic and demanding environments.Q: What are the main benefits of using this epoxy paint?

A: Benefits include excellent water, chemical, and abrasion resistance, high impact tolerance, non-toxic properties after cure, customizable colors, anti-skid options, glossy finish, and adherence to recognized industry standards (IS and ASTM).Q: How does the anti-skid system work and when should it be requested?

A: The anti-skid system is an optional feature designed to enhance slip resistance on floors. It should be requested during the order process to ensure it is incorporated during the initial paint application.Q: What is the shelf life and storage condition required for this epoxy paint?

A: Stored in sealed containers in a cool, dry, well-ventilated area away from sunlight and ignition sources, the epoxy paint maintains effectiveness for 1218 months.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bituminous Coating' category

|

GOOD EARTH MINERALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |